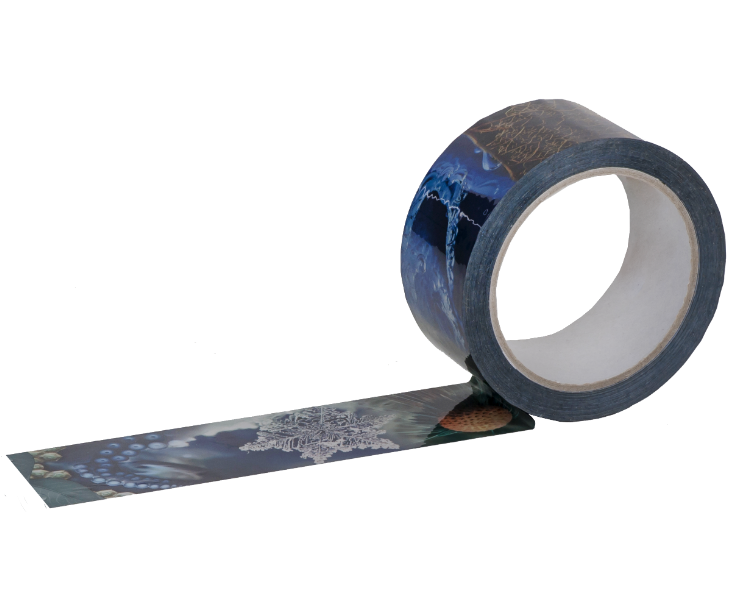

Polypropylene custom printed adhesive tapes - sandwich technology (BOPP)

od 360 ks

Medium strong in tearMedium easy to unrollVarious coils possibleVarious widths possibleSandwich printingAdheres bets in temperatures of 18 °C to 25 °C

Sandwich printing is suitable for medium to larger amount and it is a standard adhesive tape in our product portfolio. It is intended for common use when sending cardboard consignments of smaller to medium weight. Various types of special adhesives are possible.

The most common printed adhesive tapes are made of polypropylene foil. These are adhesive tapes with wider use than cheaper tapes made of PVC and they are ideal for light to medium weight cardboard consignments. As a standard, the tapes are made with acrylate adhesive and they are high tack and firm, but they are not suitable for temperatures that are too high or too low. The recommended application temperature is 18-21 °C. If you have an unheated or non-air-conditioned warehouse, the tape may not stick well. It is also necessary to consider the fact that acrylate adhesives only achieve their highest degree of tack after several hours or days. If maximum tack needs to be achieved immediately, other adhesives are used, such as for example hot melt or natural rubber. The advantage of acrylate adhesive is its high durability, slow aging and good resistance to oxidation and UV radiation.

A polypropylene tape with acrylate adhesive is of standard use in the Czech Republic as a printed tape. In other countries, tape made of PVC foil with natural rubber adhesive is still being widely used, despite being less ecological compared to polypropylene. More on polypropylene and ecology

What is BOPP?

The abbreviation BOPP stands for biaxially oriented polypropylene foil, which stretches in both directions. The foil is far more stable, its mechanical solidity increases and it also stretches less. It also looks better (has greater transparency) and its tear-resistance increases.

How does sandwich printing differ from classic printing?

At first sight, these are classic printed adhesive tapes made of polypropylene foil. The difference is that these tapes are printed on the bottom of the foil, so that the colours are between the foil and the adhesive, which is why this is called sandwich printing. During the production, print is applied directly to the foil without the adhesive in large batches on foil breadth of 600 to 1200 mm, and only then, the adhesive is applied to the printed foil on the print side. This is why the choice of special adhesives is possible in case of sandwich printing.

You will find more on sandwich printing here.

This technology is more demanding and printing is carried out on foils of nearly one meter in breadth. The adhesive is then applied to the entire breadth, and only then it is cut into the individual classic rolls. Sandwich printing technology is suitable for medium, but especially for high numbers of purchased rolls. Due to the fact that printing is carried out for nearly 12 motifs simultaneously, the preparation of production and thus also the complete production itself takes much longer than in case of classic surface printing. The total delivery period is approximately 4 to 6 weeks from the approval of graphic documentation.

As we have stated, this involves more complex production, and we therefore offer these tapes only for orders for higher numbers of rolls - from 360 rolls with print using 1to 3 colours (white colour of tape) and from 540 rolls using 4 to 6 colours (white colour of tape)

TAPE PARAMETERS:

| Tape colour: | If you choose a basic colour other than white, the choice of print colours is limited to the remaining 5.

|

Tape thickness: | We offer polypropylene adhesive tapes with standard foil thickness of 28 my, but the tape is also available in a 25 mm version.

|

| Breadth: | Regular breadth 48 mm (+- 3%).

Other breadths available on request. |

| Coil: | The regular coil is 66 m in the roll.

Upon agreement it is possible to adjust coil, for example 33 m, 132 m, 198 m .. or up to machine coil 990 m. |

Print colour: | With this technology, you can choose up to 6 colours, if the basic colour of the tape is white.

|

Adhesive: | Due to the fact that the adhesive is only applied after the application of print, it is possible to choose the type of adhesive applied. For more, see SPECIAL PRINTED ADHESIVE TAPES BOPP |