Drawn polypropylene foils (OPP and BOPP)

for production of adhesive tapes

Polypropylene foils are being drawn and are thus far more stable. For this purpose, the foil is conveyed across cylinders, which accelerate in the machine direction.

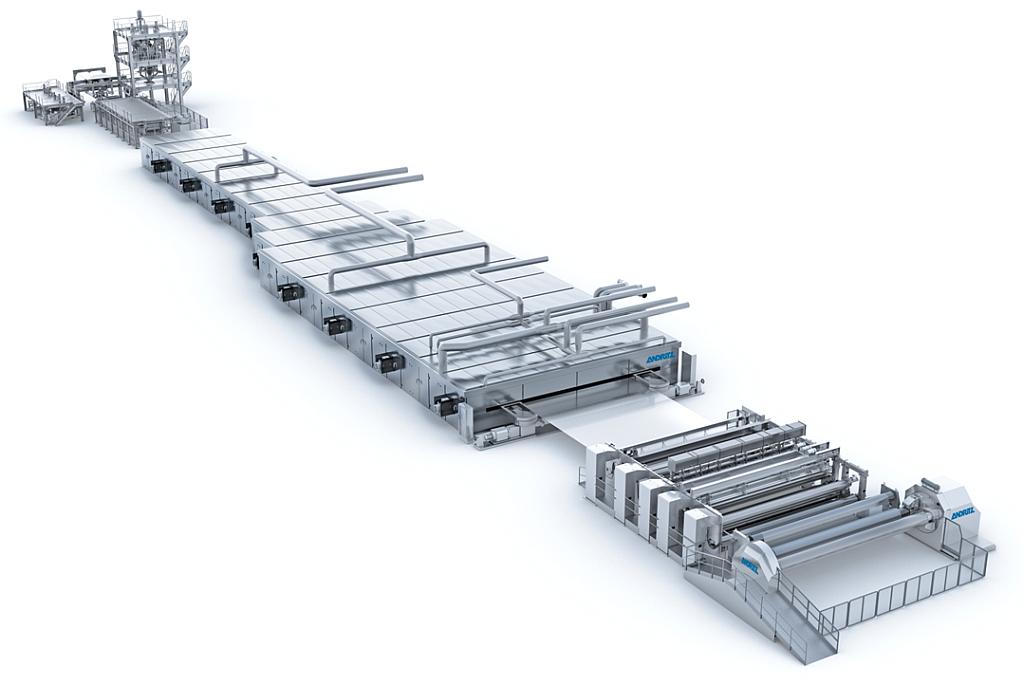

This leads to stretching the plastic material lengthwise (the so-called OPP). In order to obtain the so-called BOPP foil, it is then necessary to stretch the foil crosswise. This is carried out in a stretching unit (preheating - stretching - stabilising - cooling). To minimise internal tension, the foil is heat-stabilised at the end of the production process once more. Lengthwise as well as crosswise stretching is visible in the illustrative photograph of the production line, which is actually several dozen metres long.

The advantages of this way consist, among other things, in the lowering of vapour permeability. Mechanical firmness increases as well, the foils stretch less and have better appearance (transparency) and tear-resistance increases.

Illustrative photo: BOPP production line from Andritz AG, Raaba (Austria).

Polypropylene foils are being drawn and are thus far more stable. For this purpose, the foil is conveyed across cylinders, which accelerate in the machine direction. This leads to stretching the plastic material lengthwise (the so-called OPP). In order to obtain the so-called BOPP foil, it is then necessary to stretch the foil crosswise.