A polypropylene adhesive tape or a tape made of PVC?

It is, of course, possible to say that it is only an adhesive tape and for a normal user, the various differences are unimportant. But for a professional, who deals with the preparation of consignments or or with organising distribution on daily basis, these questions are relatively essential, so that everything would function perfectly.

First, a brief explanation of plastic foils for the production of adhesive tapes: PVC (Polyvinyl chloride) a classical plastic material known since 1935. PVC is a thermoplastic plastic material. Foil strength of 28 to 37 microns is used for adhesive tapes. It is a self-extinguishing material with excellent mechanical properties. It is a plastic material that is extremely resistant to influences from the environment. It needs to be disposed of professionally. During common incineration, parts of the emissions may be toxic. More about the material.

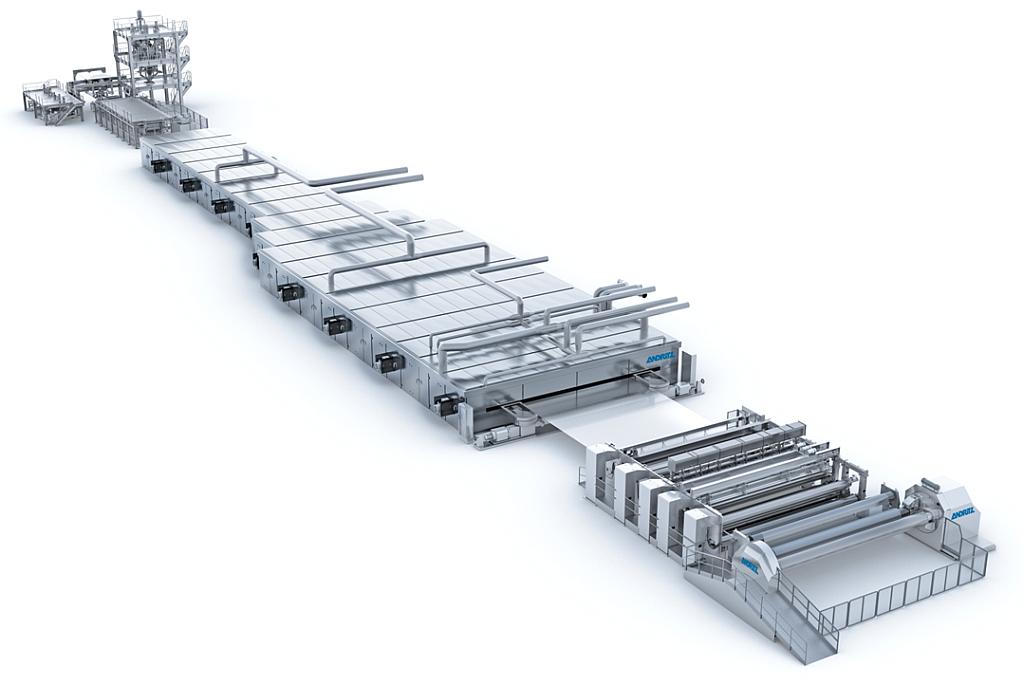

BOPP (biaxially oriented polypropylene) is thermoplastic, belongs among the most common plastic materials. Foil strength of 25 to 32 microns is used for adhesive tapes. BOPP is non-deformable crosswise. In case of lengthwise stretching, it is tear-resistant. It is non-toxic in incineration, fully recyclable. It withstands even temperature above 50 °C well. It has an assigned international plastic identification code. More about the material.

How best to recognize the difference between BOPP and PVC tapes?

At first sight, the tapes are nearly identical, but there are several tricks for determining the material.

A test with a ballpoint pen

Unroll a piece of the tape and stick its end for example onto a desk. Tighten the tape and then try to make a hole in the tape with the ballpoint pen. If the adhesive tape is torn completely, it is polypropylene foil. If you can actually manage to make a whole in the tape, though, and the tape does not tear, it is a PVC adhesive tape.

Stretch test:

Unroll a piece of adhesive tape and try to stretch the piece. You will find out that a PVC tape will gain slightly milky colour, while polypropylene will maintain its original colour.

Do you have another interesting test for determining the material? Write to us.