Polypropylene and adhesive tapes

Polypropylene (PP) is an important thermoplastic material, which only consists of carbon and hydrogen. PE and PP plastic materials are universal and cheap and can be used as material alternatives for nearly all applications made of PVC. Polypropylene is easy to shape and can be used for a wide range of products.

The basic material for the manufacturing of adhesive tapes is currently polypropylene (PP). It is an important thermoplastic material, which only consists of carbon and hydrogen. Polypropylene was first synthesized in the year 1951 by Dr. Karl Rehn at Farbwerke Hoechst and at the same time, John Paul Hogan and Robert Banks succeeded in doing so as well. Machine manufacturing began in the year 1957 during the work of Giulio Natta. Since then, the volume of PP production has been growing the most, compared to all plastic materials.

The so-called polyolefins, as well as the most significant representatives, polyethylene (PE) and polypropylene (PP), are polymers with simple structure, which do not require softeners. During the manufacturing, ingredients such as antioxidants, UV-stabilisers, heat stabilisers or substances that slow down burning may be used. Somewhere, the use of chlorine is still applied in the manufacturing, although production methods, which do not require chlorine, exist already.

Polyolefins are the least risky and they are best suited for mechanical recycling. PE and PP plastic materials are universal and cheap and can be used as material alternatives for nearly all applications made of PVC. Polypropylene is easy to shape and can be used for a wide range of products. The raw materials used for the production of polyolefins - ethylene and propylene - are considered relatively harmless for the environment.

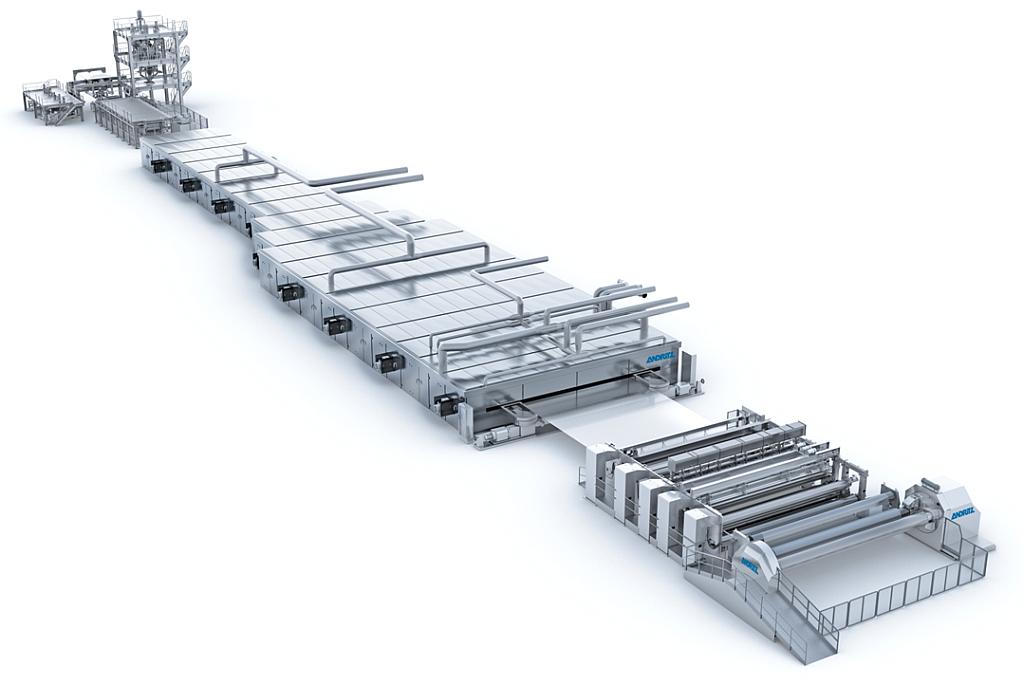

Polypropylene used for manufacturing adhesive tapes is machine-drawn in advance, so as not to stretch any further during use. More on drawn polypropylene foils.