Sandwich printing of adhesive tapes

Sandwich print, indelible print, print under adhesive, durable print between tape and adhesive - these are some names of the technology of this print. You corporate print is protected between the foil and the adhesive and cannot be deleted.

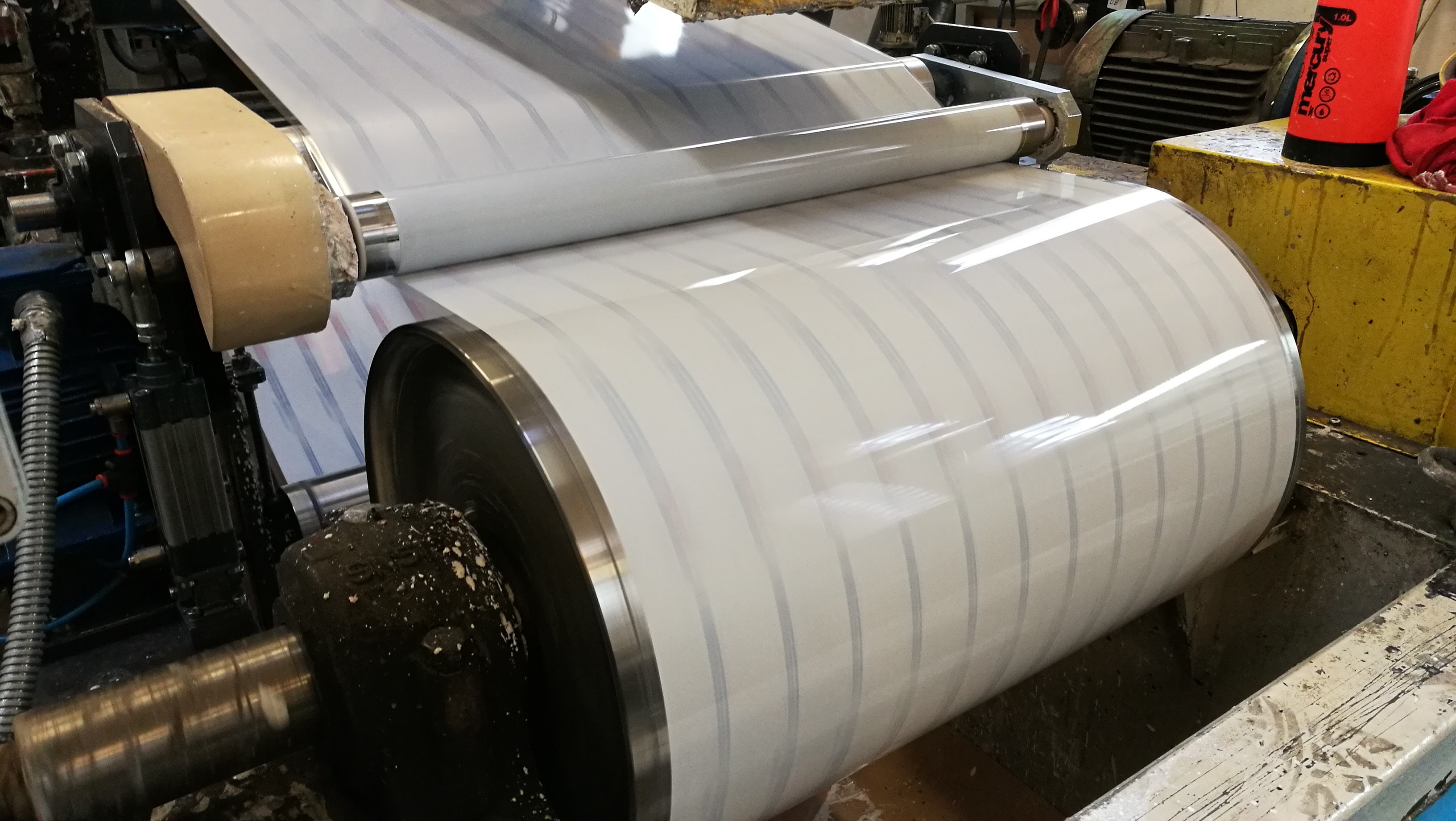

In case of sandwich printing, first a polypropylene biaxially oriented foil is printed in large batches of 600 to 1200 mm width, and only then acrylate (loud or silent) or hot melt or freezer adhesive is applied to the printed foil on the print side. A thus created printed roll with the adhesive applied is then cut into the individual rolls of the final tapes.

For this printing, it is possible to choose up to fully coloured print, and also possible to print in photographic quality.

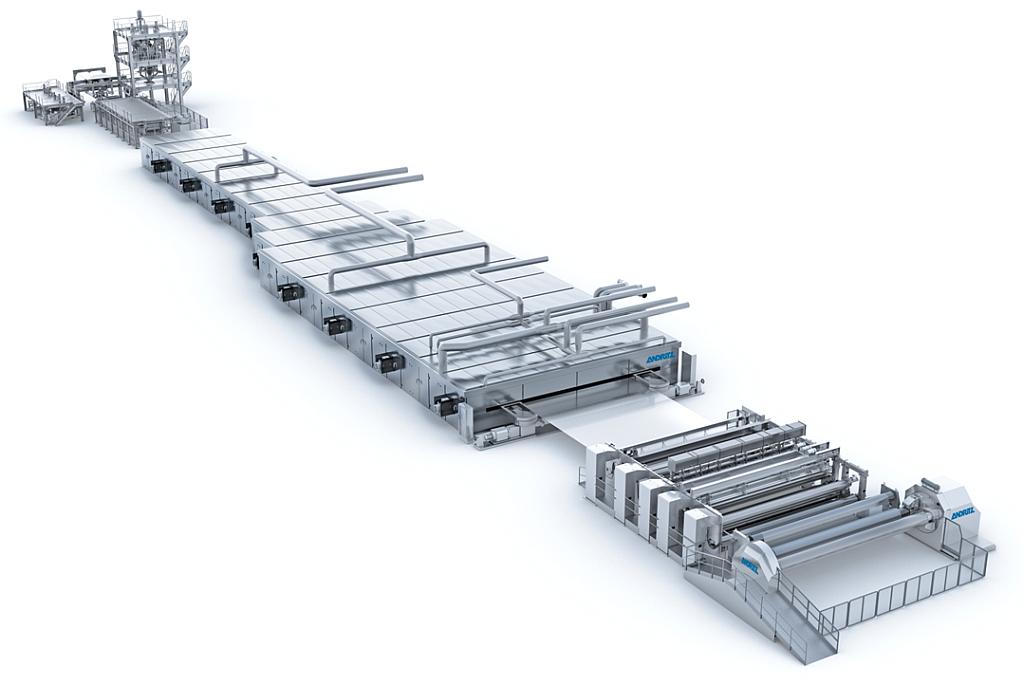

This technology has a large production capacity of fully automated manufacturing with the newest technology.

Sandwich printing technology is suitable for a medium, but especially for high numbers of purchased rolls. Due to the fact that printing is carried out in width from 600 mm, the entire production takes much longer than in a case of classic surface printing. The total delivery period is approximately 4 to 6 weeks from the approval of graphic documentation. A disadvantage of this printing is the minimum number of tapes to be produced (from roughly 432 pieces). It is unfortunately not possible to manufacture a smaller amount because printing is carried out at great speed on large width of foil. If you use up from approximately 500 pieces of tape in 6 months, though, this type of printing will suit you due to its quality.

Sandwich printing technology is suitable for a medium, but especially for high numbers of purchased rolls. Due to the fact that printing is carried out in width from 600 mm, the entire production takes much longer than in a case of classic surface printing. The total delivery period is approximately 4 to 6 weeks from the approval of graphic documentation. A disadvantage of this printing is the minimum number of tapes to be produced (from roughly 432 pieces). It is unfortunately not possible to manufacture a smaller amount because printing is carried out at great speed on large width of foil. If you use up from approximately 500 pieces of tape in 6 months, though, this type of printing will suit you due to its quality.